Goldstar Plastic Mould & Molding Ltd is an ISO 9001 registered company which is engaged in designing and building plastic injection mould mainly, located in Changan, Dongguan, Guangdong with 128 employees.

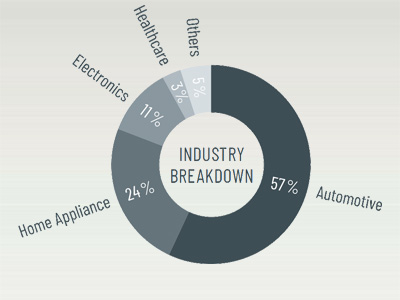

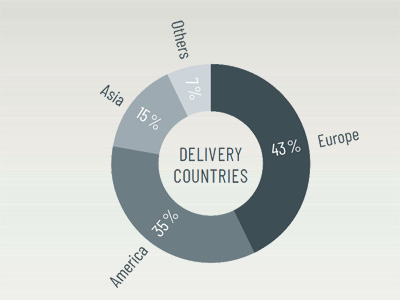

Goldstar's customers receive full in-house services, from concept to completion that includes designing, simulation, building and sampling of plastic mould and molding parts as well. Goldstar is very familiar and experienced with all DME & HASCO standards. At present, automotive parts, electronic parts, home appliances, medical and dental equipment, sporting goods, etc, composes our portfolio. After 20 years of accumulated experience and continuous improvements of quality control, Goldstar has become a reliable strategic partner of worldwide companies and has won widely praise with favorable services and qualities.

Based on technical and technological continuous updating of facilities and employees in mould and molding industry, on international quality standards allied with our internal experience and valued lessons learned, Goldstar is continuously developing and improving her services for customers, to offer the best quality results, competitive prices and shorter lead-time. Our focus has always been to establish long-term relationship with our customers. We believe nice communication in time and perfect service will bring us a luciferous future. We sincerely look forward to win-win cooperation with you.

After the approval is passed, we will contact you within 24 hours.